21 May 2025

Firebox Repair 21st May 2025

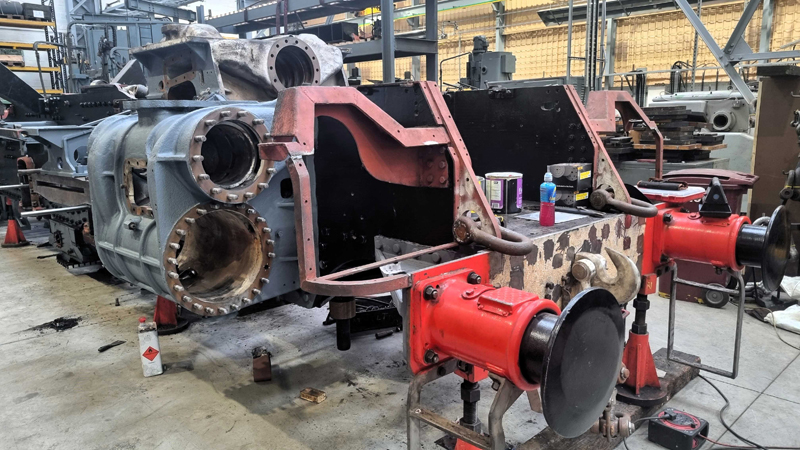

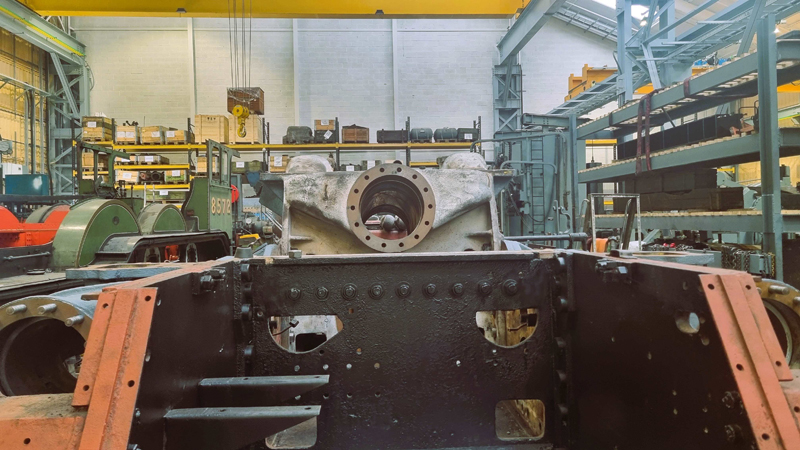

Wadebridge at Rileys 21st May 2025

Wadebridge at Rileys 21st May 2025

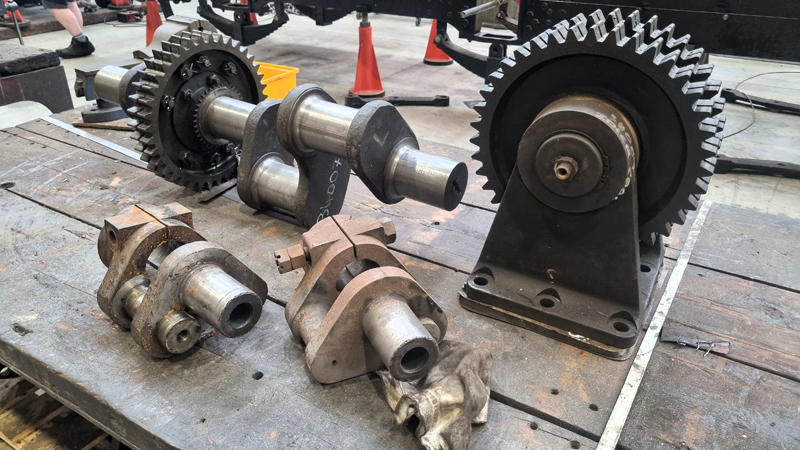

New Trailing Truck axleboxes 21st May 2025

Value Gear 21st May 2025

Wadebridge at Riley's Works 21st May 2025

23 April 2025

Engineering Report 23rd April 2025

Bury

Progress at Bury has been slow as Riley’s have confirmed that the move from Heywood to Bury has been more disruptive than expected and that winter maintenance of the three Black 5 has been highest priority.

However the more positive news is that 4 or 5 people are working on Wadebridge and they are optimistic that work can be completed by the end of 2025 for a return to Ropley Two concerns, firstly some cracks have been identified in the tube plate. The good news is that these have been addressed and along with repairs to the syphon’s are now tack welded and awaiting approval from the Boiler Inspector before final welding. The second item is thinning of the boiler plate around the foundation ring area which means the plate is thinner than the Ropley supplied corners. It believed that this is due to not enough plate being cut back on previous repairs resulting in a step. The likely solution is to cut back to thicker material and more new material would need to be added. Boiler Inspector will hopefully visit in the next week or so to discuss and authorise the proposed solution.

Work continues on the bogie and truck to complete the axle boxes and work has started on the lubrication pipework.

Other items to be completed are the motion, slide bars, horns and axle boxes.

Ropley

Boiler and Cab Fittings etc.

Work has continued at Ropley on fittings, including overhaul of drain cocks, sander valves and water glass frames.

Tender

Some work has continued on the Tender but at a slower pace. The Tender Tank was refitted, drilled and lifted again for inner bolts to be fitted.

New brake cylinder castings have arrived on site. No date yet on delivery of new electric lights for rear of Tender.

After some discussion about the brake pull rods a decision was made to pursue fabricated rods rather than forged as a lower cost option. However, the cost of getting calculations completed to satisfy Ricardo on the change of design has meant that forged rods are now the preferred option.

21 December 2024

Wadebridge Overhaul Update

1 August 2024